Introduction

Soda ash dense plays an essential role in industrial pH control, water treatment, and chemical processing across many sectors. As industries face stricter environmental regulations and increasing demand for stable, efficient operations, soda ash dense has become a preferred alkalinity source due to its controlled pH adjustment, safe handling profile, and operational reliability. Understanding what soda ash dense is and how it functions helps engineers, plant operators, and procurement teams select the right chemical for long-term performance and compliance.

This article explains soda ash dense properties, how it works in pH adjustment, its major industrial applications, and why many facilities choose it over alternative alkalis. It also highlights how sourcing through Chemtradeasia supports consistent quality and dependable supply.

Understanding Soda Ash Dense

Soda ash dense is the high-density form of sodium carbonate with the chemical formula Na₂CO₃. It is supplied as anhydrous white crystalline granules with typical purity above 99 percent. Its bulk density usually ranges from 0.9 to 1.1 g/cm³, which is almost double that of soda ash light.

This higher density delivers several operational advantages. Soda ash dense produces less dust during handling, occupies less storage space, and flows more consistently through silos, feeders, and automated dosing systems. These characteristics make it particularly suitable for large-scale industrial facilities and water treatment plants that rely on precise, continuous chemical feeding.

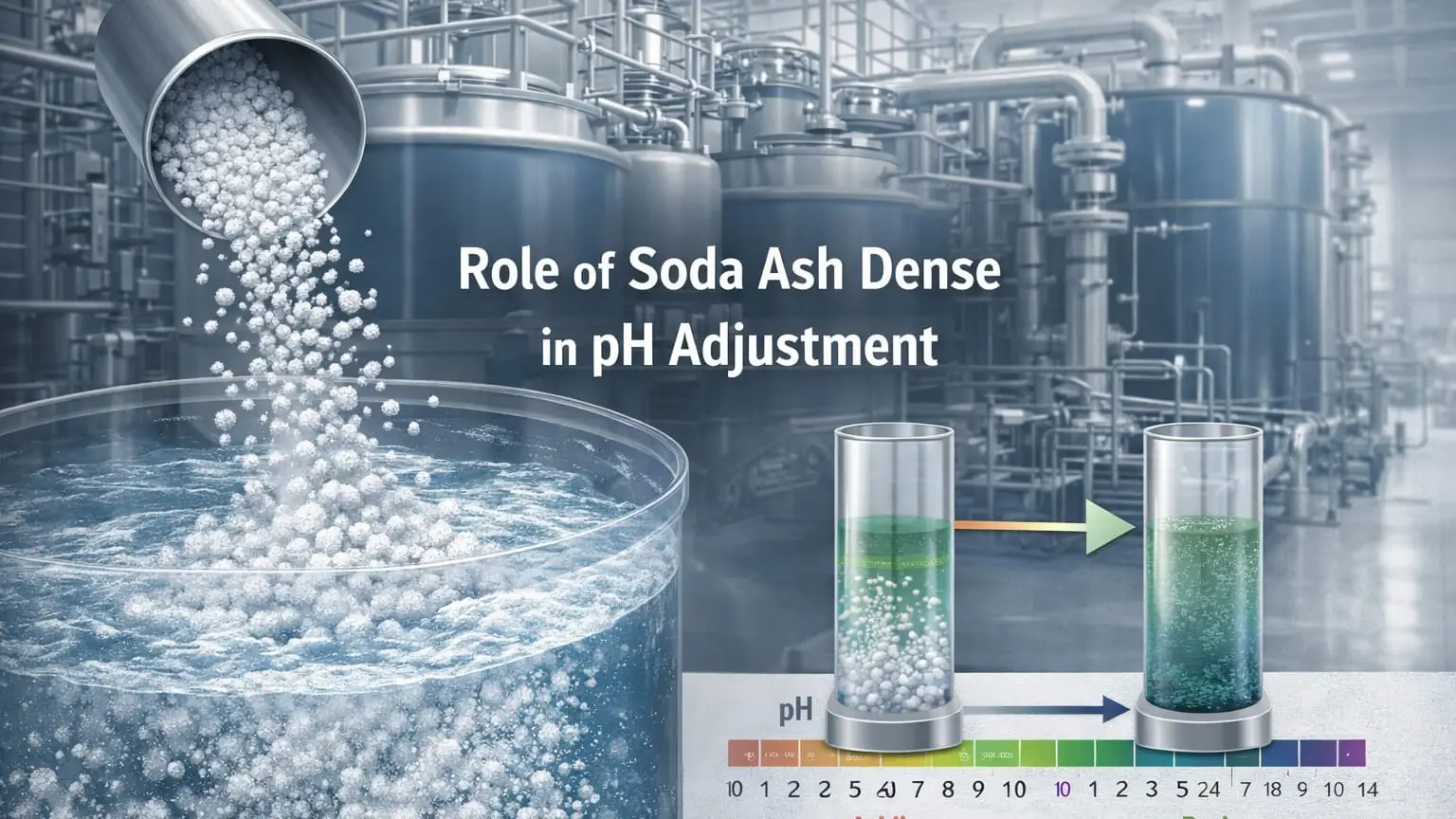

How Soda Ash Dense Adjusts pH

Soda ash dense raises pH through its natural alkalinity and buffering capacity. When dissolved in water, sodium carbonate dissociates and undergoes hydrolysis, producing hydroxide ions. These hydroxide ions neutralize excess acidity, resulting in a controlled increase in pH.

Unlike strong alkalis such as caustic soda, soda ash dense offers buffered pH control through the carbonate and bicarbonate equilibrium. This buffering effect helps maintain stable pH levels and reduces the risk of sudden pH spikes or overshooting target values. In many systems, soda ash dense can raise acidic water from pH 5 or 6 to a stable range of 7.5 to 8.5, depending on dosage and water chemistry.

This predictable behavior makes soda ash dense ideal for applications that require gradual and consistent alkalinity adjustment rather than rapid pH shifts.

Advantages of Soda Ash Dense for pH Control

Compared with other alkaline agents, soda ash dense offers a balanced combination of performance, safety, and cost efficiency.

When compared to caustic soda, soda ash dense is significantly safer to handle and store. It presents lower risks of chemical burns and localized high-pH zones. While caustic soda delivers stronger alkalinity, soda ash dense provides smoother control and buffering, which is often more desirable in sensitive processes.

Compared to lime-based products, soda ash dense dissolves cleanly without producing excessive sludge or scaling. It eliminates the need for slaking equipment and reduces maintenance demands related to clogging and sediment buildup.

Its free-flowing granular form improves dosing accuracy, reduces material loss, and supports consistent feeding. Although soda ash dense may require a higher dosage by weight compared to caustic soda, its lower handling costs and reduced maintenance often result in a favorable total cost of ownership.

Dosage and Application Considerations

Proper dosing of soda ash dense depends on initial pH, target pH, water volume, and buffering capacity. As a general reference, 50 to 100 mg/L of soda ash dense can raise the pH of soft water by approximately one unit, although site-specific testing is always recommended.

Best practice involves pre-dissolving soda ash dense in clean water to ensure even distribution. Metering pumps and injection systems should be compatible with alkaline solutions, and continuous pH monitoring is essential to prevent overdosing.

Excessive dosing may increase sodium concentrations or contribute to scaling in hard water systems, reinforcing the importance of controlled application and regular monitoring.

Sourcing Reliable Soda Ash Dense

Consistent product quality is critical for reliable pH adjustment. Variations in purity, moisture content, or particle size can affect dissolution and dosing accuracy. Partnering with established suppliers helps ensure stable performance and regulatory compliance.

Chemtradeasia connects industrial users with vetted global manufacturers of soda ash dense, providing transparent specifications, certificates of analysis, and dependable logistics. This sourcing reliability supports uninterrupted operations for water treatment plants and manufacturing facilities that operate under strict quality standards.

Conclusion

Soda ash dense is a cornerstone chemical for industrial pH adjustment, offering reliable sodium carbonate performance across water treatment and manufacturing applications. Its controlled alkalinity, buffering capacity, ease of handling, and low sludge formation make it a preferred choice over more aggressive or maintenance-intensive alkalis.

With correct dosing, proper handling, and dependable sourcing, soda ash dense supports stable operations, regulatory compliance, and cost-efficient performance. As industries continue to prioritize process optimization and environmental responsibility, working with trusted partners such as Chemtradeasia ensures consistent quality and confident pH control across diverse applications.

Leave a Comment